Thursday 30 March 2023

First silicon integrated ECRAM for a practical AI accelerator

Wednesday 29 March 2023

'Smart' bandages monitor wounds and provide targeted treatment

Monday 27 March 2023

Rectifier Diode: Guide to Functionality and Circuits

The rectifier diode lets you convert alternating current (AC) to direct current (DC). In this guide, you are going to learn how this component works and some of the circuits you create by using one.

Diodes are one of the most commonly used semiconductor devices in electronics. There are many types of diodes, but the most common one is probably the rectifier diode. It allows current to flow in only one direction and by connecting it a certain way, you can convert AC to DC.

The rectifier diode is made just like any other normal diode, but instead of being designed for small currents, it’s designed for large currents and voltages. This makes it ideal to use in power supplies.

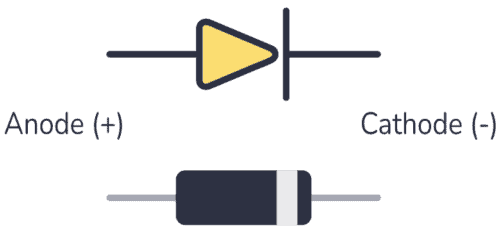

The diode symbol is made up of a triangle pointing to a straight line. The triangle represents the direction the current can flow through the diode. For example, in the picture above, the current can move to the right. But it can’t flow the other way.

How to Use a Rectifier Diode

Rectifier diodes allow current to flow in only one direction, from anode to cathode, also called Forward Bias. The rectifier diode in forward bias is made by connecting the anode to the most positive side and the cathode to the most negative side. You can see this in the example below:

In the above picture, the diode is forward-biased, which means that current can flow through it and the LED will light up. When you use a rectifier diode in this way, it acts similar to a closed switch that allows current to flow through the circuit.

What happens if you reverse the connection of the diode, like this?

When the positive terminal of the power supply is with the cathode and the negative terminal with the anode, the diode is Reverse Biased. With this type of polarization, current can’t flow through the rectifier diode, therefore the LED won’t light up in the above circuit.

What is a Half-Wave Rectifier?

In the examples above, the rectifier diode circuits used a DC power supply, which means a voltage with a fixed value. However, when this diode is connected to an AC power supply, that is where the “rectifying” property comes into play.

An AC power supply provides voltage in periodic oscillations rather than a constant value, with a positive half-cycle and a negative half-cycle, like so:

This kind of voltage is what you find in the outlets in your home. Yet, when you look at most of the electronics in your home, like your phone or laptop, you’ll find they need DC voltage to function. This is why you need rectifier diodes; they help you convert AC into DC.

Converting from AC to DC with a Rectifier Diode

The most significant step in converting AC into DC is the rectifying process, which means that it makes the negative half-cycles disappear. The simplest way to do this is with the following half-wave rectifier circuit:

Only one diode is required to construct a half-wave rectifier. During the positive half-cycle of the AC voltage, the diode is forward-biased and the current can flow through the diode. In the negative half-cycle of the AC voltage, the diode is reverse-biased and the flow of current is blocked.

What you get from this circuit is a final output that is simply the positive half-cycle waveform.

What is a Full-Wave Rectifier?

When you only get the positive voltage values with a half-wave rectifier, the negative half-cycle gets wasted. The solution to this problem is a full-wave rectifier, which lets the positive half-cycle flow and converts the negative half-cycles into positives.

In the devices you use, full-wave rectifiers are what are most commonly used to convert AC voltage to DC voltage.

A full-wave rectifier circuit made with diodes is called a diode bridge. Check out the diode bridge in the circuit below:

The diode bridge consists of four diodes – D1, D2, D3, and D4 – that are connected together. You can see how D1 and D3 share the same cathode, while D4 and D2 are connected by the anode. At the same time, the cathode of D4 is attached to the anode of D1 and the cathode of D2 is placed in the anode of D3.

The Positive Half-Cycle

During the positive half-cycle of the power supply, diodes D1 and D2 can conduct, while diodes D3 and D4 cannot because they are reverse-biased. With this arrangement, the positive half-cycle gives you a current that flows through the circuit, like so:

The Negative Half-cycle

During the negative half-cycle, diodes D3 and D4 conduct, while diodes D1 and D2 do not. Even though the circuit now receives the negative half-cycle, you can see in the picture below how the current flows through the load (output) in the same direction as before. That’s how this circuit turns the negative half-cycles into positives.

What are Some Common Rectifier Diodes?

When you need to choose a rectifier diode, you have to consider some characteristics, for example:

- Peak reverse voltage: this is the maximum voltage the diode can withstand in reverse bias before breakdown.

- Maximum forward current: the maximum value of the forward current that the diode can carry without damaging the device.

- Peak surge current: the maximum current surge that a diode can handle for a short period of time.

- Maximum voltage drop: this is the voltage that stays in the diode when it is forward-biased. Commonly, it will be 0.7v for diodes made of silicon.

The following table contains a list of the most common rectifier diodes and their characteristics.

| Diode name | Peak reverse voltage |

Max. forward current |

Peak surge current |

Max voltage drop |

|---|---|---|---|---|

| 1N4001 | 50 | 1 A | 30 A | 1.1 |

| 1N4002 | 100 | 1 A | 30 A | 1.1 |

| 1N4003 | 200 | 1 A | 30 A | 1.1 |

| 1N4004 | 400 | 1 A | 30 A | 1.1 |

| 1N4007 | 1000 | 1 A | 30 A | 1.1 |

| 1N5402 | 200 | 3 A | 200 A | 1.2 |

| 1N5406 | 600 | 3 A | 200 A | 1.2 |

| 1N5408 | 1000 | 3 A | 200 A | 1.2 |

Questions?

Do you have any questions about rectifier diodes or any feedback you want to share? Let me know in the comments below!

Copyright Build Electronic Circuits

Friday 24 March 2023

Optical switching at record speeds opens door for ultrafast, light-based electronics and computers

Tuesday 21 March 2023

Molecular teamwork makes the organic dream work

'Inkable' nanomaterial promises big benefits for bendable electronics

Monday 20 March 2023

Researchers create breakthrough spintronics manufacturing process that could revolutionize the electronics industry

Sculpting quantum materials for the electronics of the future

Friday 17 March 2023

Electronic skin as flexible as crocodile skin

Friday 10 March 2023

Some stirring required: Fluid mixing enables scalable manufacturing of soft polymer structures

Thursday 9 March 2023

New kind of transistor could shrink communications devices on smartphones

Thursday 2 March 2023

Researchers propose a simple, inexpensive approach to fabricating carbon nanotube wiring on plastic films

Key to efficient and stable organic solar cells

A team of researchers has made a significant breakthrough in the field of organic photovoltaics.

-

Do you need a MOSFET gate resistor? What value should it be? And should it go before or after the pulldown resistor? If you’re a bit impati...

-

I was first introduced to logic gates when I was around 14 years old. I had heard that computers consisted of ones and zeroes. But I didn’t...

-

A self-powered sensor could allow doctors to remotely monitor the recovery of surgical patients. The small, tube-like device is designed to ...